Hiring

Articles

Photo Gallery

16 IN X 8 FT Carbon Steel Vessel Fabricated Per ANSI B31.3 Code

16 IN X 8 FT Carbon Steel Vessel Fabricated Per ANSI B31.3 Code 18 IN X 158 IN Type 316L Dehydration Still. Rated At 15 GPM Gylcol For Conoco Refinery

18 IN X 158 IN Type 316L Dehydration Still. Rated At 15 GPM Gylcol For Conoco Refinery 2 Inch 317L SCH 10 Pipe Coil

2 Inch 317L SCH 10 Pipe Coil 2 Inch Stainless Steel Manifold Headers For Flexsys

2 Inch Stainless Steel Manifold Headers For Flexsys 24 FT Long Replacement Heat Exchanger Bundle With 389 Ea. Three-Quarters Inch O.D. .065 Wall T316L Tubes

24 FT Long Replacement Heat Exchanger Bundle With 389 Ea. Three-Quarters Inch O.D. .065 Wall T316L Tubes 24 IN X 12 FT Painted Carbon Steel ASME Code Vessel

24 IN X 12 FT Painted Carbon Steel ASME Code Vessel 3-inch Plug Valve on Right is Typical Valve Return For Repair. 3-inch Plug Valve on Left is Repaired, Tested, and Ready to Ship to Customer

3-inch Plug Valve on Right is Typical Valve Return For Repair. 3-inch Plug Valve on Left is Repaired, Tested, and Ready to Ship to Customer 40 IN O.D. X 6 FT X 0.375 Wall Vertical ASME Carbon Steel Vessel

40 IN O.D. X 6 FT X 0.375 Wall Vertical ASME Carbon Steel Vessel 42 IN O.D. X 5 FT X 0.375 Wall Carbon Steel ASME Code Vessel Reworked to Add 20 IN Flanged Opening

42 IN O.D. X 5 FT X 0.375 Wall Carbon Steel ASME Code Vessel Reworked to Add 20 IN Flanged Opening 42 Inch Carbon Steel Piping for Infineon White Oak Semi-Conductor Plant

42 Inch Carbon Steel Piping for Infineon White Oak Semi-Conductor Plant 42 Inch Carbon Steel Vessel With 10 Inch Reinforced Tangential Nozzle

42 Inch Carbon Steel Vessel With 10 Inch Reinforced Tangential Nozzle 42 X 30 Inch Carbon Steel-Trayed Filtration Column

42 X 30 Inch Carbon Steel-Trayed Filtration Column 6 Pass Carbon Steel Heat Exchanger Shell Section With Badger Flued Expansion Joint

6 Pass Carbon Steel Heat Exchanger Shell Section With Badger Flued Expansion Joint 6 Pass T316L Heat Exchanger Bundle With 468 Ea. Three-Quarters Inch O.D. U Bend Tubes

6 Pass T316L Heat Exchanger Bundle With 468 Ea. Three-Quarters Inch O.D. U Bend Tubes 8 IN SCH 40 T304L Stainless Steel Piping Polished On Interior And Exterior For a Reverse Osmosis Customer

8 IN SCH 40 T304L Stainless Steel Piping Polished On Interior And Exterior For a Reverse Osmosis Customer 8 Inch Carbon Steel Lube Oil Piping For Refinery

8 Inch Carbon Steel Lube Oil Piping For Refinery 8 Inch Stainless Steel Fabricated Piping Spools

8 Inch Stainless Steel Fabricated Piping Spools 96 IN X 10 FT Vertical T317L ASME Code Stainless Steel Vessel

96 IN X 10 FT Vertical T317L ASME Code Stainless Steel Vessel 96 Inch OD Stainless Steel Water Filtration Vessels

96 Inch OD Stainless Steel Water Filtration Vessels A Nuclear Analyzer is Used to Verify Material Composition

A Nuclear Analyzer is Used to Verify Material Composition ASME 16 Inch 1500 Pound Horizontal Gas Separator

ASME 16 Inch 1500 Pound Horizontal Gas Separator ASME 30 Inch High-Yeild Pig Launcher-Receiver

ASME 30 Inch High-Yeild Pig Launcher-Receiver ASME Section 9 Certified Welder Completes TIG Welding Process On 16 Inch Stainless Steel Pipe Spool

ASME Section 9 Certified Welder Completes TIG Welding Process On 16 Inch Stainless Steel Pipe Spool Adding a 36-ince Hand Wheel Extension to a 24-Inch, 600 Pound Velan Gate Valve

Adding a 36-ince Hand Wheel Extension to a 24-Inch, 600 Pound Velan Gate Valve All Valves Are Tagged and-or Marked to Maintain Complete Traceability

All Valves Are Tagged and-or Marked to Maintain Complete Traceability Automated Orbital Welding on 4 Inch Stainless Steel Material

Automated Orbital Welding on 4 Inch Stainless Steel Material Automated Torch-Cutting Capabilitieis From 4 to 42 Inch Carbon Steel

Automated Torch-Cutting Capabilitieis From 4 to 42 Inch Carbon Steel Chart Recording a Hydro-Test on Stainless Steel Enclosure. M.F.I. Has Hydro Capabilities to 10,000 PSI

Chart Recording a Hydro-Test on Stainless Steel Enclosure. M.F.I. Has Hydro Capabilities to 10,000 PSI Column Replacement Section 48 Inch OD X 8 FT Long, One Half Inch Thick T304L With Spiders For Shipping

Column Replacement Section 48 Inch OD X 8 FT Long, One Half Inch Thick T304L With Spiders For Shipping Confirming Layout on a Stainless Steel ASME Code Pressure Vessel

Confirming Layout on a Stainless Steel ASME Code Pressure Vessel Five Section 72 Inch Carbon Steel 90 Degree Elbow

Five Section 72 Inch Carbon Steel 90 Degree Elbow Flange Thickness is Checked to Insure Specified Thickness After Machining

Flange Thickness is Checked to Insure Specified Thickness After Machining For Over 30 Years, M.F.I. Has Fabricated Skidded Sub Syaytems For Westinghouse Electric Power Plants Worldwide

For Over 30 Years, M.F.I. Has Fabricated Skidded Sub Syaytems For Westinghouse Electric Power Plants Worldwide Heat Exchanger Tube Sheets and Baffles Are Drilled On CNC Turning Center

Heat Exchanger Tube Sheets and Baffles Are Drilled On CNC Turning Center Installation of a New Flow Line Flange On Rotary Air Head Body For a Local Independent Driller

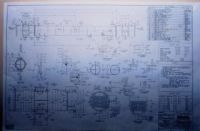

Installation of a New Flow Line Flange On Rotary Air Head Body For a Local Independent Driller M.F.I.-Generated CAD Drawing of a Heat Exchanger Designed Using Compress Calculations

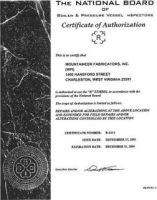

M.F.I.-Generated CAD Drawing of a Heat Exchanger Designed Using Compress Calculations Our Fabrication Shop is an ASME Certified U and PP Stampholder, Which Allows M.F.I. the Authority to Manufacture Vessels, Heat Exchangers, and Power Piping Per B31.1 and B31.3

Our Fabrication Shop is an ASME Certified U and PP Stampholder, Which Allows M.F.I. the Authority to Manufacture Vessels, Heat Exchangers, and Power Piping Per B31.1 and B31.3 Our Shop is an ASME Certified R Stampholder, Which Allows M.F.I. the Authority to Repair and Make Alterations

Our Shop is an ASME Certified R Stampholder, Which Allows M.F.I. the Authority to Repair and Make Alterations Painted 10 Inch Schedule 80 Long Radius Pipe Bend With 600 Pound Raised Face Flanges

Painted 10 Inch Schedule 80 Long Radius Pipe Bend With 600 Pound Raised Face Flanges Reducing Round Transitional Offset Stainless Steel Spool

Reducing Round Transitional Offset Stainless Steel Spool Repaired Valves Prior to Preparing For Shipping

Repaired Valves Prior to Preparing For Shipping Resistoflex-Dow Capabilities From Three Quarters to 8 Inch

Resistoflex-Dow Capabilities From Three Quarters to 8 Inch Sandblasted and Painted Dow Lined Painted Spools For Westvaco With Safety Yellow Zinc Paint

Sandblasted and Painted Dow Lined Painted Spools For Westvaco With Safety Yellow Zinc Paint Seal Rolling Alloy 2205 Tubes in Heat Exchanger

Seal Rolling Alloy 2205 Tubes in Heat Exchanger Segmented 2 IN SCH 40 Type 317L Stainless Steel Internal Pipe Coil In 84 IN O.D. Vessel

Segmented 2 IN SCH 40 Type 317L Stainless Steel Internal Pipe Coil In 84 IN O.D. Vessel Special Packing and Gasketing is Clearly Identified on Modified Valves

Special Packing and Gasketing is Clearly Identified on Modified Valves Specialty Machined Adapter Flange and Bushings Per Customer Drawings

Specialty Machined Adapter Flange and Bushings Per Customer Drawings Stainless Steel Heat Exchanger Bonnet With Interior Partitions and Mist Extractor Screen

Stainless Steel Heat Exchanger Bonnet With Interior Partitions and Mist Extractor Screen Stainless Steel Heat Exchanger; Internal Cage Assembly

Stainless Steel Heat Exchanger; Internal Cage Assembly Stainless Steel U Type ASME TEMA Heat Exchanger

Stainless Steel U Type ASME TEMA Heat Exchanger Structural Steel Fabrication of Ladders and Cages Per OSHA Standards

Structural Steel Fabrication of Ladders and Cages Per OSHA Standards Structural Steel Fabrication of Platforms Per OSHA Standards

Structural Steel Fabrication of Platforms Per OSHA Standards Tank and Piping Shwon Are Part of an Activated Carbon-Skidded Filtration System

Tank and Piping Shwon Are Part of an Activated Carbon-Skidded Filtration System Threading Capabilities From Three Quarters to Eight Inch Carbon Steel and Stainless

Threading Capabilities From Three Quarters to Eight Inch Carbon Steel and Stainless Valves Disassembled, Evaluated, and Awaiting Customer Authorization to Repair

Valves Disassembled, Evaluated, and Awaiting Customer Authorization to Repair Vic-Grooving Capabilities From Three Quarters to 24 Inch Carbon Steel and Stainless

Vic-Grooving Capabilities From Three Quarters to 24 Inch Carbon Steel and Stainless

Services

Principal Products and Services:

- Pressure Vessels

- Piping Assemblies

- ASME

- Skidded Process Units

- Launchers and Receivers

- Process Towers

- Oil and Gas Separators

- Tray Towers

- Direct and Indirect Fired Heaters

- Pulsation Bottles Drip Tanks

- Line Heaters

- Machine Shop Services

- High Pressure Piping Headers

- Heat Exchangers/Coolers

- Storage Tanks

- Meter Runs

- Plate Rolling

- Engine Lathes

- Horizontal and Vertical Boring Mills

- CNC Milling and Drilling

- Surface Grinding

- Pressure Testing -Hydrostatic, Pneumatic, Helium Leak detection, Nitrogen Sensitive Leak

- Weld, Mechanical, and Industrial Engineers --On Site

Cleaning and Painting

- Surface cleaning and Pickling

- Blasting, Priming, and Painting

- Sand Blasting, Conventional and Airless Spray (virtually all paint and coating systems)

- New 25,000 Sq. Ft. Coating Facility.

History

Mountaineer Fabricators, Inc. designs and manufactures ASME pressure vessels, pre-fabricated piping assemblies and modular skids. Our company began operations in 1923 and has grown to become one of the nation's best fabrication and machining operations. The company was purchased from the original family owners in 2004 and moved into the newly constructed facilities in Nitro , West Virginia .

Bob Hammack, Jr. purchased the company he had managed for many years and retained the workforce with all of its expertise. The average experience of the welders, machinist, engineers, and managers is over twenty years. With a new facility designed to meet today's fabrication, machining and coating requirements, our productivity, workmanship and quality is unparalleled.

Mountaineer Fabricators, Inc. is an ASME certified manufacturer with capabilities to both fabricate and repair pressure vessels, heat exchangers and pressure piping. We currently maintain "U", "R", and "S" Stamps as well as the "NB" stamp indicating our ability to register completed work for our customers. Pre-fabricated "Power Piping" is manufactured to ASME Sections B-31.1 (including ASME Section 1), B-31.3 as well as API. Our welders are certified to both ASME Section IX and API-1104 requirements. Our welding and procedures are extremely advanced and will continue to include new technology as it becomes available. We have an Engineering Department capable of complete design calculation to ASME Section VIII, Division 1 requirements using state of the art software (Compress® by Codeware), and with our up-to-date computer aided design software (AutoCAD) we are ready to handle the standard construction or tackle the tough and out of the ordinary projects.

A large portion of our business includes the manufacturing of prefabricated piping assemblies, launchers/receivers, and valve settings. From general assembly drawings, we create isometric drawings, procure materials, fabricate the piping assemblies, x-ray, inspect, hydrostatic test, blast, and coat to meet the needs of our customers. Our assemblies are utilized by the oil, power, chemical, and natural gas industries to greatly reduce construction cost.

Our goal at Mountaineer Fabricators, Inc. is to provide the customer with the best in quality and cost for all of their fabrication and machining requirements while providing a safe and secure environment for our employees.